Oleh {0}

Oleh {0}

Testing instruments (14)

Testing instruments (14) Total floorspace (4,000㎡)

Total floorspace (4,000㎡) Quality management certified

Quality management certified Sample-based customization

Sample-based customizationCNC Turning Service

Machined Metal and Plastic Prototypes & Production Parts in as Fast as 7 Day | SGS | ISO9001:2015 Registered

All uploads are secure and confidential.

All uploads are secure and confidential.

CNC Turning Overview

XLF has serviced for more than 2,000 clients, including those with CNC lathes and turning centers, XLF provides you with the

capacity and capabilities your project needs, while also delivering the most competitive pricing, lead times, and instant

quotation. We will manufacturability feedback to ensure that your part is optimized for the CNC turning process and fits the

requirements you need. Our on-demand manufacturing platform can deliver high-quality metal or plastic turned parts for

rapid prototyping or low-to-high volume production runs.

You can get an instant quote from a 3D/CAD file >>>

CNC Materials

Overview: What is CNC Turning?

The Basics Of CNC Lathes

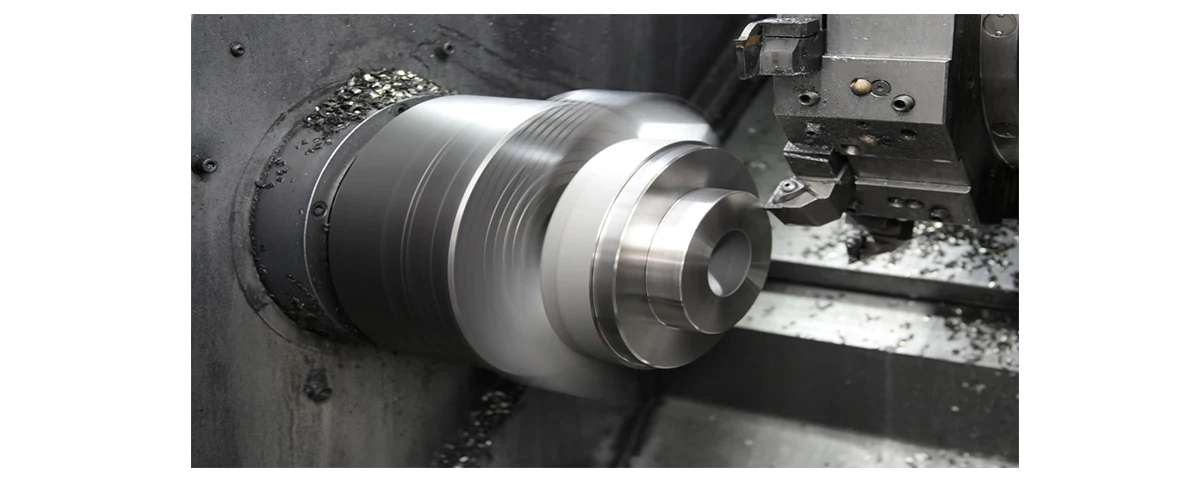

CNC lathe machines, also called live tooling lathes, are ideal for cutting any symmetrical cylindrical or spherical parts.

Characteristically, a lathe spins a workpiece on a vertical or horizontal axis, while a fixed shaping instrument moves

around it on a more or less linear path. The act of cutting a workpiece on a CNC lathe is called turning.

How CNC Turning Works

CNC lathes use a subtractive method to create the desired shape. With the G-Code created, a blank bar of stock

material is loaded into the chuck of the lathe's spindle. The chuck holds the workpiece in place while the spindle

spins. When the spindle is up to speed, a stationary cutting tool is brought into contact with the workpiece to

remove material until the desired geometry is achieved.

There are many operations that can be performed on a live tooling lathe, including facing, threading,

knurling, drilling, boring, reaming, and taper turning. Different operations require tool changes

and can increase cost and set-up time.

When all machining operations are completed, the part is cut from the stock for further post-processing. The CNC

lathe is then ready to repeat the operation with little-to-no set-up time in between.

Types Of CNC Lathes

There are many types of lathes, but the most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes

are unique in that stock material is fed through a guide bushing, allowing the tool to cut nearer to the point of support,

which makes them particularly useful for long, slender turned parts and micromachining. Some Swiss-type lathes

also come equipped with a second tool head that operates as a CNC mill, allowing them to perform multiple machining

operations without having to move the workpiece to a different machine. This makes Swiss-type lathes extremely cost

-effective for complex turned parts.

Benefits Of CNC Turning

Like CNC mills, CNC lathes can be easily set up for high repeatability, which makes them great for everything from

rapid prototyping to low and high-volume production. Multi-axis CNC turning centers and Swiss-type lathes allow

for multiple machining operations in one machine. making them a cost-effective option for complex geometries

that would otherwise require multiple machines or tool changes in a traditional CNC mill.